Tesla Mechanical Designs’ Cost-Effective Drafting Cuts Costs and Accelerates Manufacturing

Tesla Mechanical Designs’ drafting minimizes errors, reduces material waste, & accelerates manufacturing, delivering cost savings & faster time-to-market.

Meticulous drafting is our clients’ first line of defense against costly errors—turning design intent into manufacturing success, every time.”

CA, UNITED STATES, July 1, 2025 /EINPresswire.com/ -- Tesla Mechanical Designs, a leader in design and engineering solutions, highlights its strategic approach to mechanical drafting as a critical driver for manufacturing success. By focusing on meticulous and cost-effective drafting practices, the company delivers tangible value to clients, enabling significant savings, faster innovation, and seamless integration from design concept to manufactured product.— Divya Dave, Asst. Director, Tesla Mechanical Designs

In modern manufacturing, the quality of mechanical drafting often serves as the foundational pillar for project success. Inaccurate or ambiguous blueprints can lead to costly errors, extensive rework, and delays that ripple through the entire production chain. Tesla Mechanical Designs’ methodology ensures that every drawing is not just a visual representation, but a precise, unambiguous instruction set, meticulously crafted to prevent such issues and optimize the manufacturing journey.

𝐀𝐜𝐜𝐮𝐫𝐚𝐜𝐲 𝐚𝐭 𝐄𝐯𝐞𝐫𝐲 𝐒𝐭𝐚𝐠𝐞 𝐌𝐢𝐧𝐢𝐦𝐢𝐳𝐞𝐬 𝐑𝐞𝐰𝐨𝐫𝐤 𝐚𝐧𝐝 𝐌𝐚𝐱𝐢𝐦𝐢𝐳𝐞𝐬 𝐒𝐚𝐯𝐢𝐧𝐠𝐬

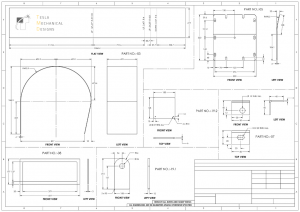

A primary benefit of Tesla Mechanical Designs’ rigorous drafting approach is its ability to drastically reduce costly errors and material waste for clients. Drafting, when executed precisely, acts as the first line of defense against manufacturing inefficiencies. The company's team of skilled drafters and engineers adheres to stringent internal standards and industry best practices, ensuring every dimension, tolerance, and notation is accurate and clearly communicated.

Errors in drafting can lead to components that don't fit, assemblies that fail, or parts that are manufactured out of specification. Correcting these issues on the shop floor or, worse, after product delivery, incurs significant expenses in terms of scrapped materials, machine downtime, labor hours for rework, and delayed shipments. Tesla Mechanical Designs’ meticulous process virtually eliminates these scenarios by identifying and rectifying potential conflicts during the drafting phase. This proactive error prevention capability is invaluable, leading to substantial cost savings for its clients.

Using advanced CAD platforms, Tesla Mechanical Designs engineers create dimensionally perfect drawings with zero tolerance for ambiguity. Every bend radius, hole placement, and tolerance stack is analyzed against applicable standards and client-specific production capabilities. This proactive scrutiny catches potential clashes like incompatible bend sequences or tooling conflicts before they reach the factory floor.

The result? 𝐓𝐚𝐧𝐠𝐢𝐛𝐥𝐞 𝐜𝐨𝐬𝐭 𝐬𝐚𝐯𝐢𝐧𝐠𝐬:

• Material waste reduced by up to 30% through optimized nesting and flat pattern accuracy.

• Rework costs minimized by ensuring designs are "right-first-time," backed by DFM (Design for Manufacturability) validation.

• Compliance with standards guarantees seamless supplier handoffs and quality consistency.

"Tesla Mechanical Designs’ drafting eliminated $18k in rework costs for our HVAC enclosure line. Their attention to tolerancing and weld callouts was game-changing." — Manufacturing Director, Industrial Equipment Firm (USA)

𝐄𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐭 𝐃𝐫𝐚𝐟𝐭𝐢𝐧𝐠 𝐟𝐨𝐫 𝐅𝐚𝐬𝐭𝐞𝐫 𝐃𝐞𝐥𝐢𝐯𝐞𝐫𝐲

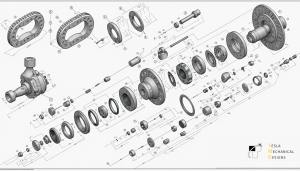

Speed-to-market separates industry leaders from laggards. Tesla Mechanical Designs’ drafting methodology transforms this pressure into a competitive edge. By integrating parametric modeling, automated BOM generation, and real-time collaboration tools, the team compresses drafting cycles by 40–60% without compromising on the accuracy.

𝐊𝐞𝐲 𝐝𝐫𝐢𝐯𝐞𝐫𝐬 𝐨𝐟 𝐭𝐡𝐢𝐬 𝐚𝐜𝐜𝐞𝐥𝐞𝐫𝐚𝐭𝐢𝐨𝐧 𝐢𝐧𝐜𝐥𝐮𝐝𝐞:

• Rapid Iteration: Cloud-based platforms enable instant design updates, allowing clients to test multiple configurations in hours, not weeks.

• Prototype-Ready Drafts: Drawings include machine-readable GD&T (Geometric Dimensioning and Tolerancing), enabling direct CNC programming for same-day prototyping.

• Cross-Platform Compatibility: Drafts export seamlessly to CAM software (e.g., Mastercam, Siemens NX), slashing pre-production delays.

𝐃𝐫𝐚𝐟𝐭𝐢𝐧𝐠 𝐟𝐨𝐫 𝐒𝐞𝐚𝐦𝐥𝐞𝐬𝐬 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧

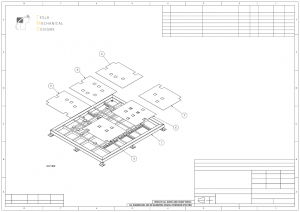

Traditional drafting methods often lead to delays due to ambiguous or incomplete drawings, requiring frequent queries and clarifications. Tesla Mechanical Designs prioritizes comprehensive and unambiguous drafting. This commitment ensures manufacturers and fabricators receive instructions that are ready for immediate action, drastically shortening the communication loop between design and production teams.

𝐘𝐨𝐮𝐫 𝐂𝐨𝐦𝐩𝐞𝐭𝐢𝐭𝐢𝐯𝐞 𝐄𝐝𝐠𝐞

By reducing the inherent friction and delays associated with traditional drafting, Tesla Mechanical Designs empowers clients to innovate more quickly and introduce new products to the market ahead of competitors. Our focus on efficient, high-quality drafting acts as a direct catalyst for swift project progression, giving you a significant edge in the race to market.

𝐔𝐧𝐢𝐟𝐲𝐢𝐧𝐠 𝐃𝐞𝐬𝐢𝐠𝐧 𝐚𝐧𝐝 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧: 𝐁𝐫𝐢𝐝𝐠𝐢𝐧𝐠 𝐂𝐨𝐦𝐦𝐮𝐧𝐢𝐜𝐚𝐭𝐢𝐨𝐧 𝐆𝐚𝐩𝐬

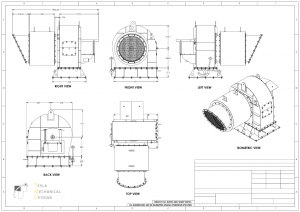

Tesla Mechanical Design's drafting services play a pivotal role in unifying design intent with manufacturing reality, ensuring seamless project execution. A common challenge in product development is the disconnect between what designers envision and what manufacturers can efficiently produce. Drafting serves as the critical communication bridge, translating abstract design ideas into concrete, actionable manufacturing instructions.

Our drafters work closely with both designers and manufacturing engineers, ensuring that every drawing incorporates design for manufacturability (DFM) principles. This collaborative approach means components are not just designed to function, but also designed to be produced effectively and economically. Key manufacturing considerations—such as material limitations, tooling requirements, assembly sequences, and quality control checkpoints—are integrated into the drawings from the earliest stages.

This integration reduces misinterpretations and ensures that all stakeholders, from engineers and procurement specialists to machine operators, are working from a single, unified source of truth. Drawings generated by Tesla Mechanical Designs contain all necessary information, from detailed part geometries and assembly instructions to surface finishes and inspection criteria. This eliminates guesswork, minimizes errors on the production line, and fosters a more collaborative environment where design intent is faithfully translated into a physical product.

The most sophisticated design fails if production teams misinterpret intent. Tesla Mechanical Designs eradicates this disconnect by treating drafting as a collaborative language that aligns designers, engineers, and machinists.

Their unique approach includes:

1. Context-Rich Annotations: Drawings embed manufacturing notes (e.g., "Laser-cut before bending," "Deburr edges post-stamping") directly into views.

2. 3D PDF Walkthroughs: Interactive documents allow production teams to rotate, section, and interrogate models, clarifying complex assemblies.

By proactively addressing potential manufacturing challenges through comprehensive drafting, Tesla Mechanical Designs enables a truly streamlined design-to-production workflow. This unification results in higher quality products, fewer production bottlenecks, and a more predictable manufacturing timeline for its clients.

𝐃𝐫𝐚𝐟𝐭𝐢𝐧𝐠 𝐚𝐬 𝐚 𝐒𝐭𝐫𝐚𝐭𝐞𝐠𝐢𝐜 𝐀𝐬𝐬𝐞𝐭

Tesla Mechanical Designs proves that drafting is far more than lines on paper. It is the strategic nexus where design intent becomes manufacturing reality. By minimizing rework, accelerating development, and unifying teams, their cost-effective drafting methodology delivers faster ROI, higher quality, and unmatched scalability. In an era where manufacturing margins are razor-thin, this approach isn’t just efficient; it is transformative.

𝐀𝐛𝐨𝐮𝐭 𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧𝐬

Tesla Mechanical Designs is a global engineering design and automation company with close to a decade of experience in delivering world-class 3D modeling, on-demand & custom manufacturing, and drafting solutions. Focusing on quality, speed, and innovation, the company serves clients in multiple industries across North America, Europe, and Asia-Pacific. For more information on how Tesla Mechanical Designs can transform your manufacturing capabilities, please visit its website at www.teslamechanicaldesigns.com.

Divya Dave

Tesla Mechanical Designs

+1 214-699-6163

email us here

Visit us on social media:

LinkedIn

Bluesky

Instagram

Facebook

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.